User: Hi, I’ve heard about temperature controller, but I don’t really understand how they work. Can you explain them to me in simple terms?

Specialist: Of course! A temperature controller is a device that maintains and regulates temperature in a system. It takes input from a sensor, compares it to a setpoint, and adjusts the output to reach or maintain the desired temperature. Think of it like a thermostat for your home, but it can be much more precise and tailored to industrial needs.

User: That’s interesting. How is it used in the food industry?

Specialist: In the food industry, maintaining the right temperature is critical for food safety and quality. For instance:

- Freezers: A temperature controller ensures the freezer maintains the correct sub-zero temperature for storing frozen goods.

- Racks and Table Trollies: These are used for keeping food warm during transport or display. The controller maintains consistent heating to prevent spoilage.

User: What about other applications, like in machines or incubators?

Specialist:

- Machine Manufacturing Industry: Here, temperature controllers are used in processes like plastic molding or metalworking, where specific temperature ranges are crucial for product quality.

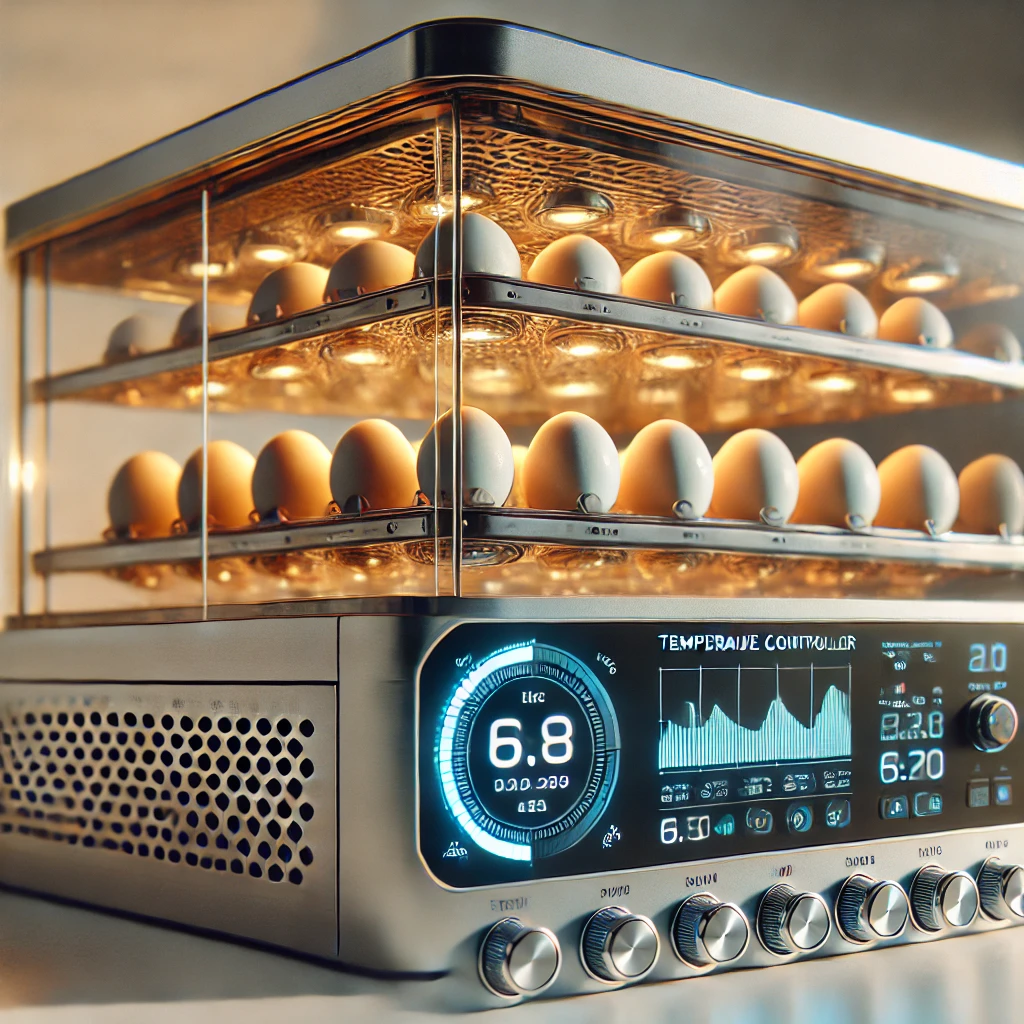

- Incubators: In medical or biological applications, incubators rely on precise temperature control for growing cultures or hatching eggs. The controller ensures a stable and uniform environment.

- Hatching: For poultry, temperature controllers maintain the optimal temperature and humidity for egg incubation, ensuring successful hatching rates.

User: Okay, that’s clear. But what features make these controllers unique?

Specialist: Great question! Some common features include:

- Accuracy: They can maintain precise temperatures within a small range.

- Programmability: Many models allow you to set schedules or different modes for various needs.

- Alarms and Safety: They provide alerts if the temperature goes out of range, ensuring safety.

- Connectivity: Advanced models can be connected to a network for remote monitoring and control.

User: How are they different from what competitors offer?

Specialist: The differences often come down to:

- Build Quality: Some brands offer more robust or specialized models for harsh environments.

- Ease of Use: Certain controllers have more intuitive interfaces or better software.

- Customization: High-end models may allow more configuration for specific industries.

- Integration: Some controllers are better suited for integration with existing systems or smart technologies.

User: What about similarities with competitors?

Specialist: Most temperature controllers share core functionalities:

- They all measure, compare, and adjust temperature.

- Common inputs like thermocouples or RTDs (Resistance Temperature Detectors) are used.

- Most models offer basic alarm and safety features.

The choice often depends on the specific application and budget.

User: I see. How do I decide which one is best for my needs?

Specialist: Start by identifying your requirements:

- What is the temperature range you need?

- How critical is precision for your process?

- Do you need advanced features like remote monitoring or multiple setpoints?

- What is the environment—clean, industrial, or harsh?

Once you know these details, you can match them with the right product specifications.

User: Thank you! This was very informative. I’ll get back to you with more details about my requirements.

Specialist: My pleasure! Feel free to reach out anytime.

Great read!