In the world of industrial automation, few systems are as critical — or as underestimated — as the humble pick-and-place mechanism. Whether it’s placing circuit boards on a conveyor or sorting bottles on a packaging line, speed and accuracy are everything.

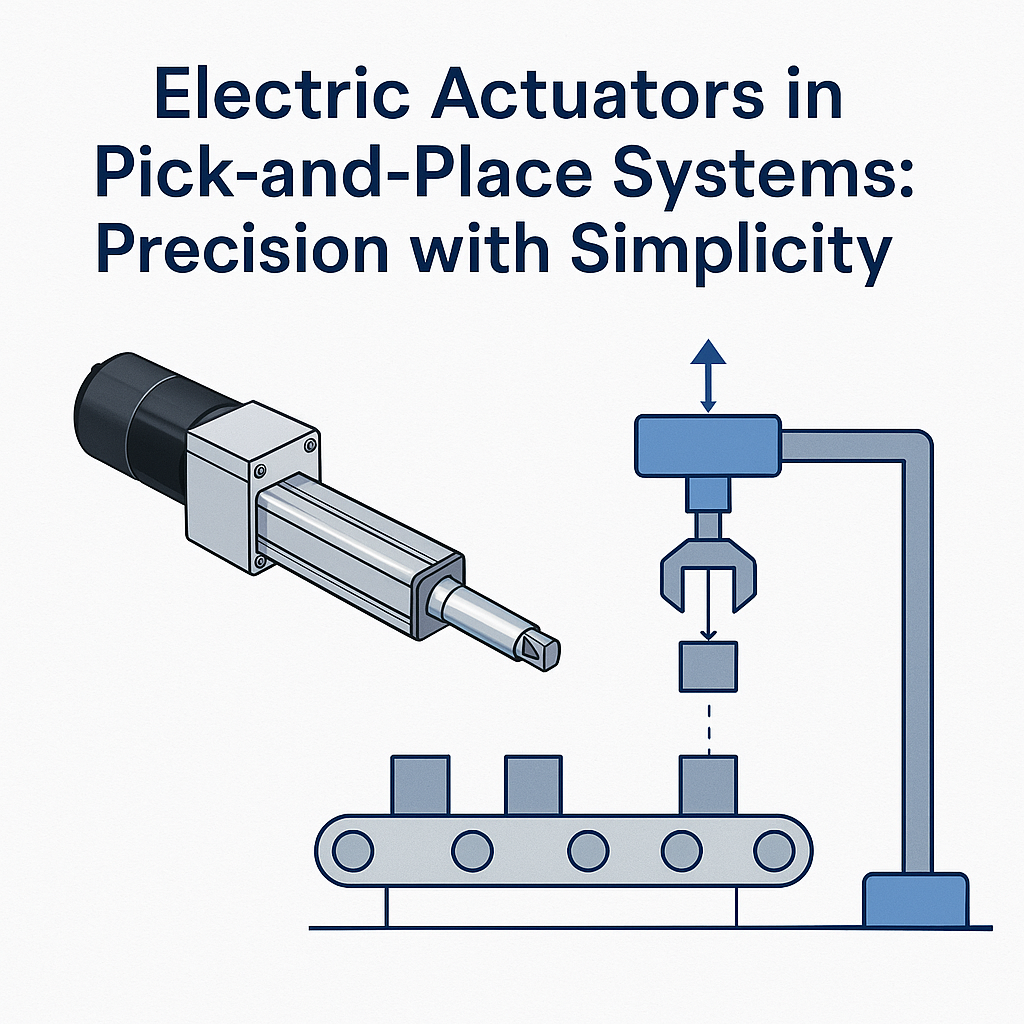

And at the heart of many modern pick-and-place systems today lies a silent workhorse: the electric linear actuator.

Why Pick-and-Place Systems Matter

Pick-and-place automation plays a key role in:

- Electronics manufacturing (PCB assembly, chip placement)

- Pharmaceuticals (bottle sorting, tablet packing)

- Food & Beverage (filling lines, carton handling)

- Automotive components (precision parts placement)

In all these, repeatability, motion control, and speed determine productivity. Any misalignment or delay causes a ripple effect across the production line.

That’s why many industries are now turning to electric actuators for motion control — replacing pneumatics and manual operations.

The Power of Electric Actuators: Simple, Yet Precise

Electric actuators offer a set of advantages that make them perfect for pick-and-place tasks:

1. Precise Positioning

No guesswork. Electric actuators can move to exact positions within fractions of a millimeter — critical for placing delicate or tiny items like electronic components or medical devices.

2. Programmable Motion Profiles

Need a fast pick and slow place? Want acceleration control? Done. With electric actuators, you can customize:

- Speed

- Stroke length

- Acceleration/deceleration

All controlled via a PLC, HMI, or motion controller.

3. Clean Operation

No air hoses, no compressors, no oil leaks. Perfect for sterile or dust-sensitive environments like cleanrooms and food production areas.

4. Compact Design

Electric actuators come in slim, modular sizes — ideal for tight spaces and robot arms.

5. Low Maintenance

No valves or seals to fail. Just plug and play. Maintenance is minimal, uptime is maximized.

Real Use Case: PCB Assembly Line

At a mid-sized electronics plant in Chennai, the assembly line for power supply boards faced frequent alignment errors and mechanical failures using pneumatic pick-and-place arms.

After switching to electric actuators with programmable stroke and sensor feedback, the team saw:

- 98% accuracy in part placement

- 20% faster cycle times

- 60% drop in machine downtime

- Easier troubleshooting using diagnostics built into the actuator driver

Simple Integration, Big Results

Electric actuators are easy to integrate into existing setups. You don’t need to redesign the whole line. Most models can be directly controlled via:

- PLC I/O

- Step/Direction signals

- Serial commands (Modbus, CANopen, etc.)

This makes them an easy upgrade with instant results.

Ideal for Smart Automation

In Industry 4.0 environments, electric actuators support:

- Real-time feedback (position, load, fault alerts)

- Integration with SCADA systems

- Energy-efficient motion control

- Cloud monitoring and predictive maintenance

They’re not just components — they’re smart devices.

Final Words: Precision + Simplicity = Productivity

Pick-and-place systems don’t need to be complex. With electric actuators, you get a clean, efficient, and precise solution that delivers every single cycle.

Whether you’re automating electronics, packing tablets, or handling tiny mechanical parts, electric actuators bring the perfect balance of precision and simplicity — helping your line run faster, smoother, and smarter.

Nice Article

Nice Blog