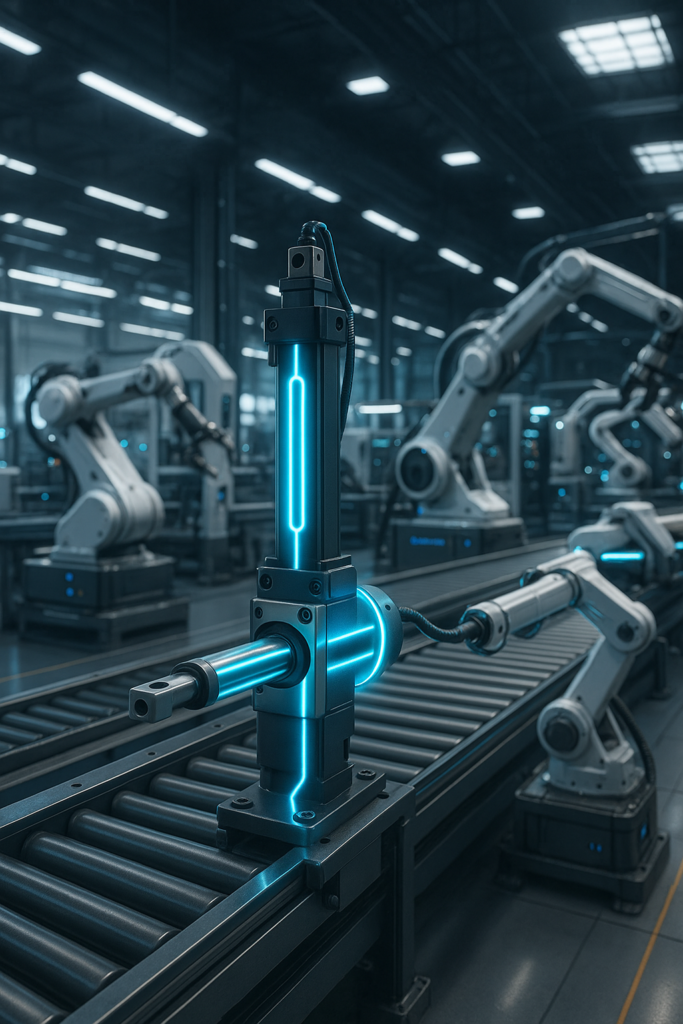

In today’s fast-paced manufacturing world, industries are moving toward smarter, cleaner, and more efficient solutions. One of the key technologies driving this shift is the electric linear actuator system. These devices, designed to convert rotary motion into linear movement, are now at the core of modern industrial automation.

What Makes Linear Actuators Unique?

Unlike hydraulic or pneumatic systems, electric linear actuators offer precise control, reliability, and energy efficiency. They don’t require complex fluid systems, making them cleaner, easier to maintain, and more cost-effective in the long run.

Key Features of Linear Actuators in Automation:

- High Precision – Accurate positioning for tasks like cutting, pressing, or adjusting.

- Low Maintenance – No leaks, pumps, or compressors required.

- Compact Design – Easy to integrate into machines and equipment.

- Programmable Control – Seamlessly integrates with PLCs, IoT, and smart systems.

- Eco-Friendly – Consumes less energy compared to hydraulics.

Industrial Applications of Linear Actuator Systems

Linear actuators are transforming how industries design and operate their machines:

- Material Handling Systems – Automating lifting, pushing, and adjusting conveyor belts.

- Packaging & Assembly Lines – Precision motion ensures faster production with fewer errors.

- Valve & Brake Controllers – Reliable control in heavy-duty machinery and rigs.

- Irrigation & Agricultural Systems – Automating spraying, lifting, and regulating equipment.

- Healthcare & Mobility Solutions – Adjustable hospital beds, patient lifts, and assistive devices.

- Special Purpose Machines (SPMs) – Tailor-made motion systems for custom industrial needs.

The Shift Toward Electric Actuation

Industries are increasingly replacing hydraulic and pneumatic systems with electric actuators because of their:

- Energy efficiency

- Precision and repeatability

- Cleaner operation with no fluid contamination risks

- Ability to integrate with digital automation platforms

This shift not only boosts productivity but also aligns with global sustainability goals.

The Future of Industrial Automation with Linear Actuators

As industries adopt Industry 4.0 practices, the demand for smart actuators is rising. Integrated with sensors, controllers, and digital interfaces, linear actuators will continue to shape the future of automated manufacturing, robotics, and intelligent systems.

Good Article

I must admit I was impressed after reading this blog.