The oil & gas industry works under extreme conditions every day. High pressure, high temperature, and hazardous fluids are common. Because of this, precise control is not optional—it is essential. This is where valve controller become critical.

It helps to regulate flow, manage pressure, and improve safety. As a result, oil & gas companies rely on them across upstream, midstream, and downstream operations. Without proper valve control, efficiency drops and risks increase.

Overview of the Oil & Gas Industry

The oil & gas industry is divided into three major sectors.

First, upstream operations focus on exploration and extraction. Next, midstream operations handle transportation and storage. Finally, downstream operations manage refining and distribution.

Although each sector is different, they all face similar challenges. For example, they must control dangerous fluids continuously. Therefore, automation and valve control systems are widely used throughout the industry.

Valve Requirement for the Oil & Gas Industry

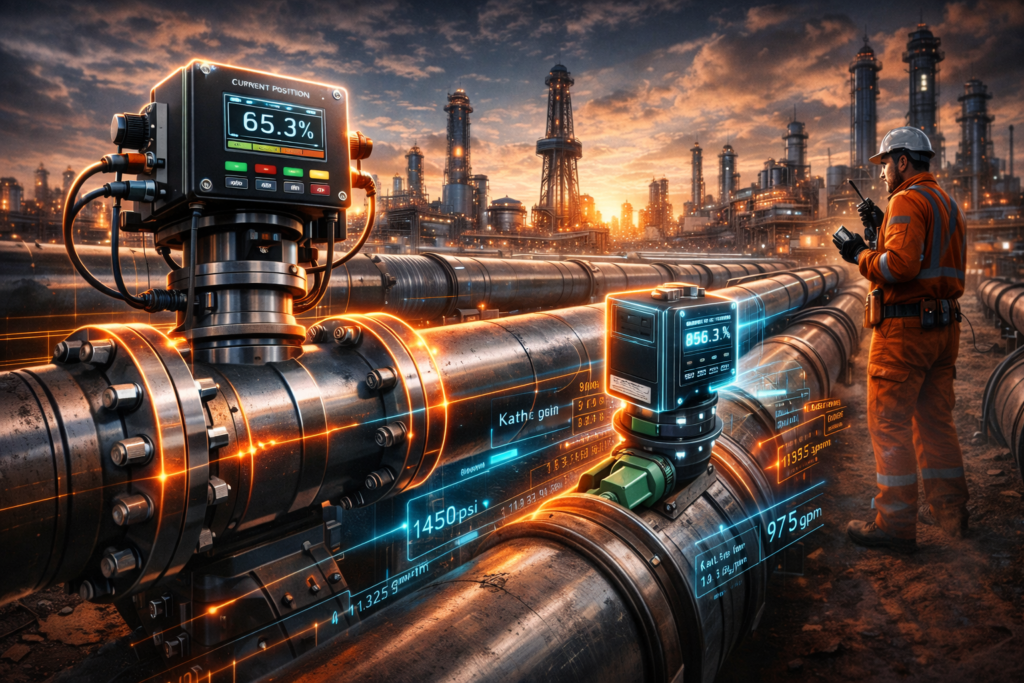

Valves are used everywhere in oil & gas plants. However, valves alone cannot deliver accuracy. That is why valve controllers are required. Valve controllers constantly adjust valve positions. As a result, they help maintain stable flow, pressure, and temperature. Moreover, they improve safety during abnormal conditions. In addition, valve controllers reduce manual operation. This not only saves time but also lowers human error.

Role of Valves in Oil & Gas Operations

Valves control how fluids move through pipelines and equipment. They start flow, stop flow, or change flow rate.

For example, valves isolate equipment during maintenance. Similarly, they protect systems during emergencies. When connected to valve controllers, they respond faster and more accurately.

Therefore, valves and valve controllers always work together as a single system.

Types of Valves Used in Oil & Gas Operations

Different processes require different valve types.

- Gate valves are used for isolation

- Globe valves provide precise flow control

- Ball valves offer quick shut-off

- Butterfly valves control large flows

- Check valves prevent reverse flow

However, each valve type needs a suitable actuator and controller. Without proper control, even the best valve will fail to perform well.

How Valve Controller Work in Oil & Gas Applications

Valve controllers act as the final control element. They connect control systems to mechanical valves. First, the controller receives signals from PLCs or DCS systems. Next, it activates the actuator using pneumatic, electric, or hydraulic power. Then, the valve adjusts the flow path. As a result, flow increases, decreases, or stops. Because of this automation, operators can control valves remotely. This improves both efficiency and safety.

Where Valve Controller Are Used in Oil & Gas

Upstream (Extraction)

Valve controllers are used at wellheads and gathering systems. Here, they control the initial flow from wells. At the same time, they protect equipment from pressure spikes.

Midstream (Transport)

In pipelines, valve controllers regulate flow over long distances. Therefore, they prevent pressure loss and pipeline damage.

Downstream (Refining & Distribution)

In refineries, valve controllers manage complex processes. For instance, they control temperature, mixing, and reaction rates. As a result, product quality improves and waste is reduced.

Factors Influencing Valve Selection in Oil & Gas Applications

Several factors affect valve and controller selection.

- Operating pressure and temperature

- Fluid type and corrosion risk

- Required control accuracy

- Environmental conditions

- Automation compatibility

Because conditions are harsh, reliability becomes a top priority. Therefore, robust valve controllers are always preferred.

Importance of Valve Reliability and Performance in the Industry

Valve failure can cause serious problems. For example, it may lead to leaks, downtime, or accidents. Reliable controllers help prevent these issues. They provide stable operation, fast response, and continuous monitoring. Moreover, they reduce maintenance costs and production losses. As a result, oil & gas companies invest in high-performance valve control solutions.

Regulatory Standards and Compliance for Valves in Oil & Gas

The oil & gas industry follows strict regulations. These include API, ISO, IEC, and ATEX standards.

It must meet these requirements. Otherwise, operations may become unsafe or non-compliant. Therefore, certified and tested valve controllers are essential for industrial approval.

Conclusion

In conclusion, valve controllers are vital to the oil & gas industry. They ensure safe flow control, pressure management, and process optimization. From wellheads to refineries, they support every stage of operation. When combined with reliable products like Kathir Sudhir Automation’s valve controllers, industries achieve better safety, higher efficiency, and long-term reliability.