In the world of engineering and automation, the term “actuator” holds immense significance. From robotics and aerospace to industrial machinery and automotive applications, actuators play a crucial role in enabling precise motion control. In this blog post, we will delve into the meaning and functionalities of actuators, exploring their various types, working principles, and applications. Whether you’re a student, a professional, or simply curious about the world of automation, this comprehensive guide will provide you with a solid understanding of what actuators are and how they shape the modern world. Let’s discuss and understand what is actuator meaning.

Understanding Actuators

Definition and Purpose

Defining an Actuator

Actuators are devices responsible for converting input energy into motion, allowing for precise control and manipulation of physical systems.

The Role of Actuators in Motion Control

Actuators serve as the mechanism that enables machines and systems to move, adjust, and perform specific tasks.

Types of Actuators

Hydraulic Actuators

Utilizing the power of fluids, hydraulic actuators generate motion through the movement of pressurized liquids.

Pneumatic Actuators

Pneumatic actuators rely on compressed air or gas to create linear or rotary motion, providing quick response times and simple designs.

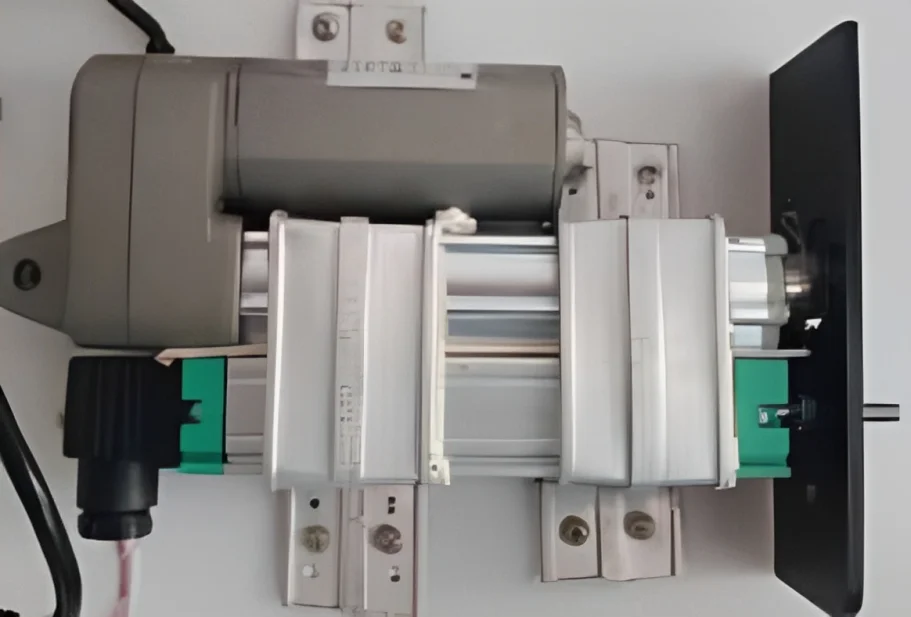

Electric Actuators

Electric actuators use electric motors to convert electrical energy into mechanical motion, offering precise control and high accuracy.

Electro-Hydraulic Actuators

These actuators combine the benefits of hydraulic and electric actuators, incorporating hydraulic power with electric control.

Electromechanical Actuators

Electromechanical actuators employ the movement of electric motors or solenoids to produce mechanical motion.

Piezoelectric Actuators

Piezoelectric actuators utilize the piezoelectric effect to generate motion by applying voltage to certain materials.

Shape Memory Alloy Actuators:

These actuators employ shape memory alloys that can change shape when subjected to thermal or electrical stimuli.

Thermal Actuators

Thermal actuators use the principle of thermal expansion to produce motion by heating or cooling certain elements.

Working Principles

Actuator Components and Mechanisms

Actuators consist of essential components such as motors, gears, linkages, and feedback systems to convert energy into motion.

Translational and Rotary Motion

Actuators can provide linear or rotational motion, depending on the application and system requirements.

Actuators in Action

Industrial Applications

Robotics and Automation

Actuators drive the precise movements of robotic arms and manipulators, enabling automation in manufacturing processes.

Manufacturing and Assembly Lines

Actuators play a vital role in positioning, lifting, and manipulating components during assembly and production processes.

Material Handling and Conveyor Systems

Actuators control the movement of conveyor belts, sorting systems, and robotic material handling equipment.

Precision Machining

Actuators enable the accurate control of cutting tools, milling machines, and CNC systems for precise machining operations.

Packaging and Labeling

Actuators drive the movement of packaging machinery, including sealing, labeling, and filling equipment.

Automotive Applications

Engine Control Systems

Actuators regulate the flow of fuel and air, control valve timing, and adjust throttle position in automotive engines.

Suspension and Steering Systems

Actuators control the dampers and suspension systems to provide a smooth and comfortable ride, while also enabling precise steering control.

Braking Systems

Actuators actuate the brake calipers, controlling the braking force and ensuring effective braking performance.

Power Windows and Mirrors

Actuators enable the smooth and precise movement of power windows and mirrors in modern vehicles.

HVAC Controls

Actuators regulate airflow, temperature, and vent positions in heating, ventilation, and air conditioning (HVAC) systems.

Aerospace and Defense Applications

Aircraft Flight Control Systems

Actuators are instrumental in controlling a wide range of aircraft movements, including ailerons, elevators, rudders, and flaps.

Satellite and Spacecraft Deployment

Actuators facilitate the deployment of solar panels, antennas, and other components in satellites and spacecraft.

Weapon Systems and Turret Control

Actuators drive the movement and aiming of weapon systems, turret rotations, and gun elevations.

Landing Gear Actuation

Actuators extend and retract landing gears during takeoff and landing operations in aircraft.

Medical and Biotechnology Applications

Surgical Robots

Actuators enable precise movements in surgical robots, assisting surgeons in performing minimally invasive procedures with high accuracy.

Prosthetics and Orthotics

Actuators power artificial limbs, allowing for natural and controlled movements to enhance the mobility of individuals with limb loss or disabilities.

Laboratory Automation

Actuators drive the movement of pipettes, robotic arms, and sample handling systems in automated laboratories.

Drug Delivery Systems

Actuators control the release of drugs and fluids in medical devices such as insulin pumps and infusion systems.

Factors to Consider When Selecting an Actuator

Load Capacity and Force Requirements

The actuator must be capable of exerting the necessary force to move the intended load.

Speed and Precision

Considerations for the required speed and accuracy of the motion.

Environmental Considerations

Factors such as temperature, humidity, and exposure to chemicals or harsh conditions should be taken into account.

Power Source and Control Systems

Compatibility with the available power source and control systems is crucial for seamless integration.

Cost and Maintenance

The cost of the actuator, as well as maintenance requirements and expected lifespan, should be considered.

Advancements in Actuator Technology

Miniaturization and Micro actuators

Ongoing advancements have led to the development of smaller, more compact actuators suitable for miniaturized applications.

Smart Actuators and Intelligent Control

Actuators equipped with sensors and intelligent control systems allow for adaptive and responsive motion control.

Energy Efficiency and Sustainability

Efforts are being made to enhance the energy efficiency of actuators, reducing power consumption and environmental impact.

Integration of Actuators with Sensors and AI

Actuators are being integrated with sensors and artificial intelligence to enable autonomous and proactive motion control systems.

Conclusion

Actuators are the driving force behind precise motion control in a wide range of industries. From manufacturing and robotics to aerospace and healthcare, these essential components have revolutionized the way we interact with technology. Understanding the meaning and functionality of actuators is crucial for engineers, designers, and enthusiasts alike. By exploring the various types, applications, and advancements in actuator technology, we gain a deeper appreciation for their significant contributions to our modern world. With continuous advancements in this field, we can expect actuators to become even more compact, efficient, and intelligent, paving the way for further innovation in automation and beyond. Embracing the power of motion control through actuators opens up endless possibilities for enhancing efficiency, accuracy, and automation across diverse industries. For Customized Linear Actuator kindly visit Our Website.