In the world of engineering and automation, actuators play a crucial role in converting various forms of energy into mechanical motion. Whether you’re familiar with the term or not, actuators are present in our everyday lives, driving countless devices and systems. From industrial machinery to household appliances, actuators enable the smooth and controlled movement that we often take for granted. In this blog post, we will delve into Actuators Meaning, explore their different types, and shed light on their importance in achieving linear motion. So, let’s dive in!

Actuators Meaning: Unveiling the Basics

To grasp the concept of actuators, we need to understand their fundamental meaning. In simple terms, an actuator is a device or mechanism responsible for converting energy into physical motion. This energy can take various forms, such as electrical, hydraulic, pneumatic, or even thermal. Actuators act as the driving force behind the movement of objects, allowing for precise control and automation.

Actuators Meaning: The Key to Linear Motion

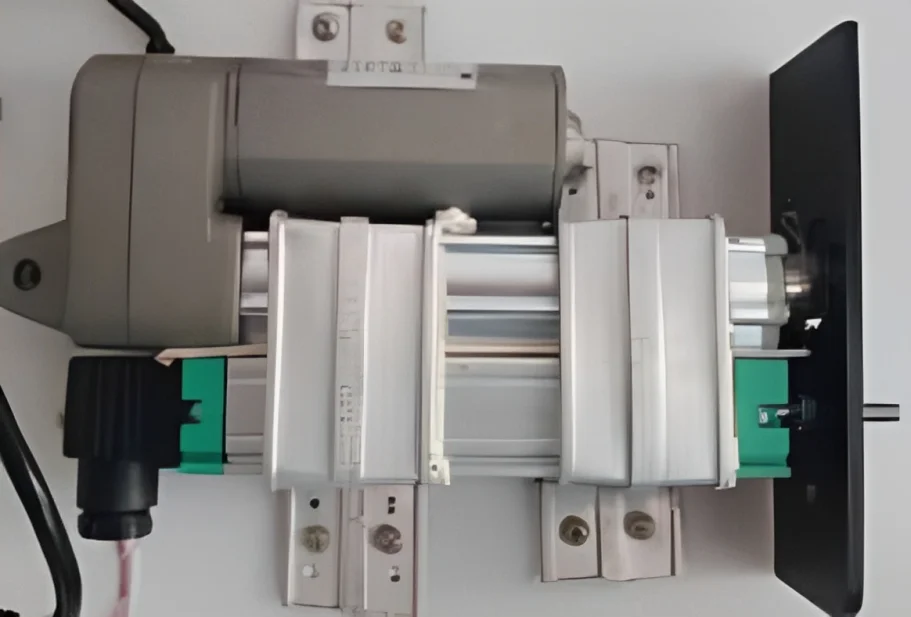

One particular type of actuator that deserves special attention is the push-pull linear actuator. As the name suggests, this type of actuator generates linear motion by pushing and pulling. It is widely used in applications that require controlled and synchronized movement, such as robotics, manufacturing, and automotive systems.

The push-pull linear actuator consists of several key components. A motor, typically electric, provides the necessary energy for the actuator to function. This motor drives a lead screw or a belt, which is responsible for translating the rotary motion of the motor into linear motion. A carriage or a slider is attached to the lead screw or belt, and it moves along a linear rail or guide rods, ensuring smooth and precise movement.

The applications of push-pull linear actuators are vast and varied. In the manufacturing industry, these actuators are employed in assembly lines for precise positioning, picking, and placing tasks. They are also utilized in robotics to enable precise control over the movement of robot arms, enhancing their dexterity and versatility. Additionally, push-pull linear actuators find applications in the automotive sector, where they play a vital role in controlling various mechanisms, such as throttle valves and braking systems.

Different Types of Actuators

While push-pull linear actuators are widely used, there are several other types of actuators available, each with its own unique characteristics and applications. Let’s take a closer look at a few prominent examples:

Hydraulic Actuators

These actuators utilize pressurized fluid, usually oil or water, to generate mechanical motion. They offer high force capabilities and are often employed in heavy-duty applications, such as construction machinery and aerospace systems.

Pneumatic Actuators

Pneumatic actuators use compressed air to create motion. They are known for their rapid response, simplicity, and relatively low cost. Pneumatic actuators find applications in various areas, including valve control, robotics, and automation.

Electric Actuators

Electric actuators, powered by electricity, are highly versatile and can be found in numerous industries. They come in different forms, such as rotary electric actuators, which produce rotational motion, and linear electric actuators, which generate linear motion.

Piezoelectric Actuators

These unique actuators rely on the piezoelectric effect, where certain materials deform when an electric current is applied to them. Piezoelectric actuators are highly precise and find applications in areas such as nanotechnology, optics, and medicine.

The Importance of Actuators in Automation

Actuators are at the heart of automation, enabling machines and systems to perform tasks with accuracy, efficiency, and repeatability. By converting various forms of energy into mechanical motion, actuators facilitate the seamless operation of automated processes, reducing human effort and increasing productivity.

In manufacturing, actuators play a vital role in assembly lines, controlling the movement of robots and machines for precise positioning and manipulation of components. They ensure that every part is placed with accuracy and consistency, resulting in high-quality products and improved production rates.

In the field of robotics, actuators allow for the intricate and coordinated movement of robot arms, enabling them to perform complex tasks with precision. From industrial robotics used in factories to surgical robots assisting in delicate medical procedures, actuators are the driving force behind their motion and functionality.

Moreover, actuators contribute to advancements in various industries. In the automotive sector, they are essential for controlling mechanisms such as throttle valves, fuel injection systems, and steering systems. In aerospace, actuators are used in aircraft control surfaces, landing gear systems, and flap mechanisms. They are even utilized in the field of renewable energy, playing a crucial role in solar panel tracking systems and wind turbine blade positioning.

Conclusion

In conclusion, actuators are the unsung heroes behind the smooth and controlled motion we encounter in countless devices and systems. From the humble push-pull linear actuators to the more complex hydraulic and electric variants, these devices convert energy into mechanical motion, driving automation and enhancing precision in various industries. Understanding the meaning and importance of actuators allows us to appreciate the incredible role they play in shaping our modern world. For more Details kindly visit our website.